Catalytic Converter - LH Manifold

Catalytic Converter-3.0L LH Manifold

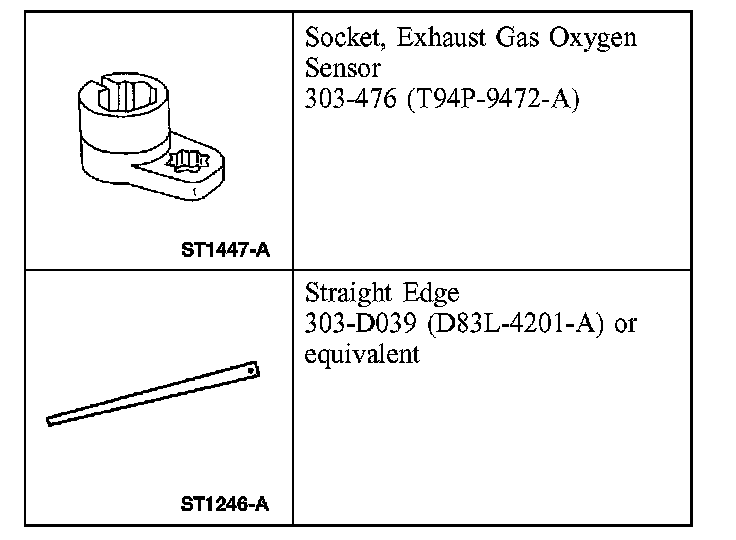

Special Tool(s)

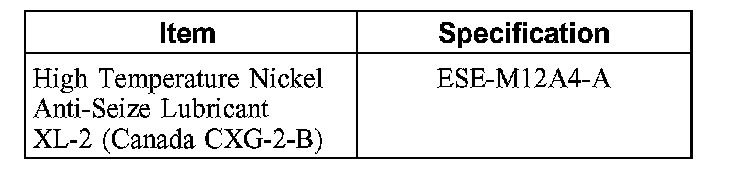

Material

Removal

1. With the vehicle in NEUTRAL, position it on a hoist.

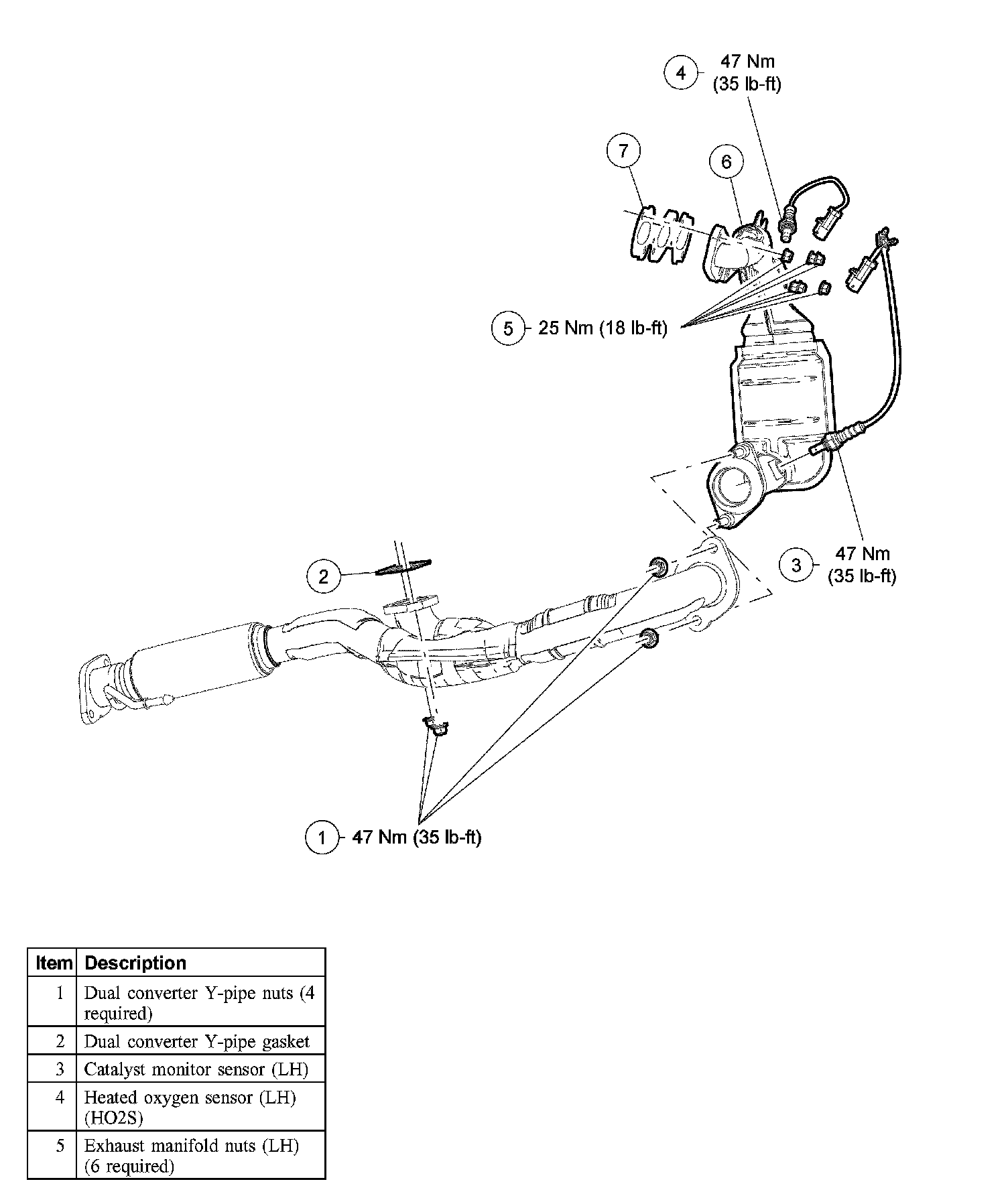

2. NOTE: If installing a new converter, remove the heated oxygen sensor (HO2S) and the catalyst monitor sensor for installation in the new converter.

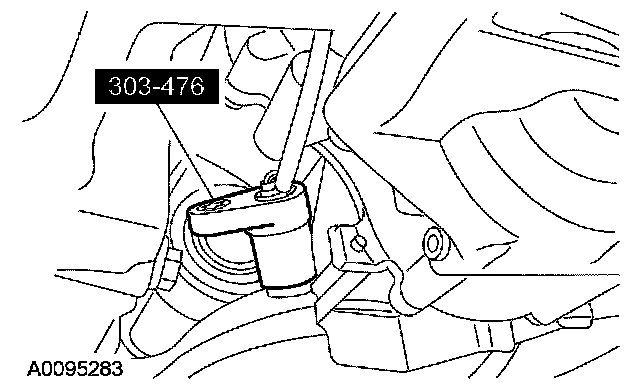

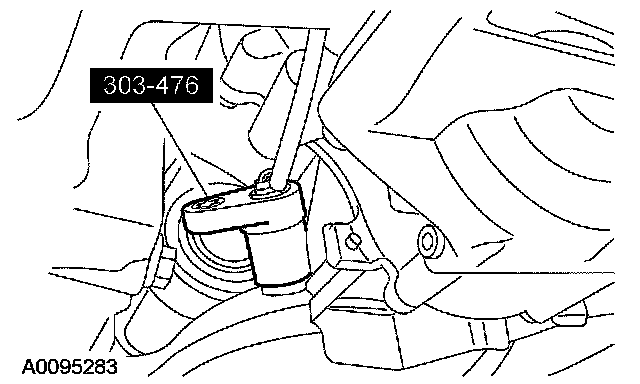

Using the special tool, disconnect the LH HO2S and the LH catalyst monitor sensor electrical connectors.

3. CAUTION: Do not allow the dual converter Y-pipe to hang from the flexible end. Support the dual converter Y-pipe.

Remove the 4 dual converter Y-pipe nuts and position the dual converter Y-pipe aside.

^ Discard the gasket.

4. Rotate the accessory drive belt tensioner clockwise, and position the drive belt aside.

5. Remove the A/C compressor nut and the 2 A/C compressor bolts, and position the A/C compressor aside.

6. Remove and discard the 6 LH exhaust manifold nuts.

7. Remove the LH catalytic converter from the vehicle.

8. Remove and discard the exhaust manifold gasket.

Installation

1. CAUTION: If the warpage is greater than 0.76 mm (0.03 inch) replace the catalytic converter.

Inspect the catalytic converter for warpage across the manifold flange area.

2. Position a new LH exhaust manifold gasket.

3. CAUTION: Failure to tighten the catalytic converter nuts to specification before installing the converter bracket bolts will cause the converter to develop an exhaust leak.

CAUTION: Failure to tighten the catalytic converter nuts to specification a second time will cause the converter to develop an exhaust leak.

NOTE: Make sure to tighten the nuts in the sequence in 2 stages.

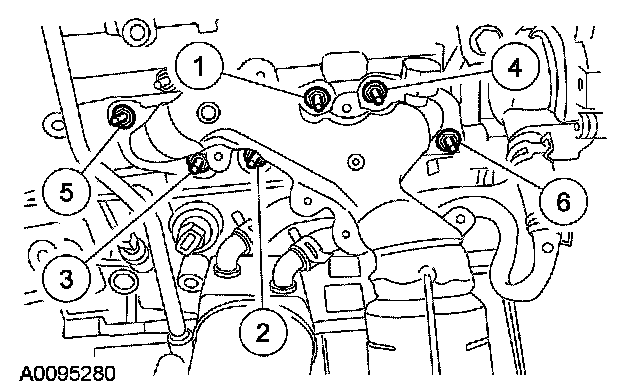

Position the LH catalytic converter and tighten the 6 exhaust manifold nuts in the sequence shown.

^ Stage 1: Tighten to 25 Nm (18 ft. lbs.).

^ Stage 2: Tighten to 25 Nm (18 ft. lbs.).

4. Position the A/C compressor and install the 2 A/C compressor bolts and the A/C compressor nut.

^ Tighten to 25 Nm (18 ft. lbs.).

5. Rotate the accessory drive belt tensioner clockwise and install the belt. For correct drive belt installation, refer to Drive Belts, Mounts, Brackets and Accessories.

6. Position the dual converter Y-pipe gasket.

7. Position the dual converter Y-pipe and install the 4 dual converter Y-pipe nuts.

^ Tighten the nuts to 47 Nm (35 ft. lbs.).

8. NOTE: Make sure to apply anti-seize lubricant to the threads of the H02S before installation

If installing a new converter, install the H02S and the catalyst monitor sensor using the special tool.

^ Tighten to 47 Nm (350 ft. lbs.).

9. Connect the LH H02S and catalyst monitor electrical connectors.